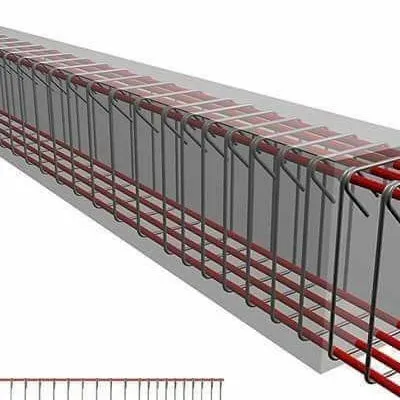

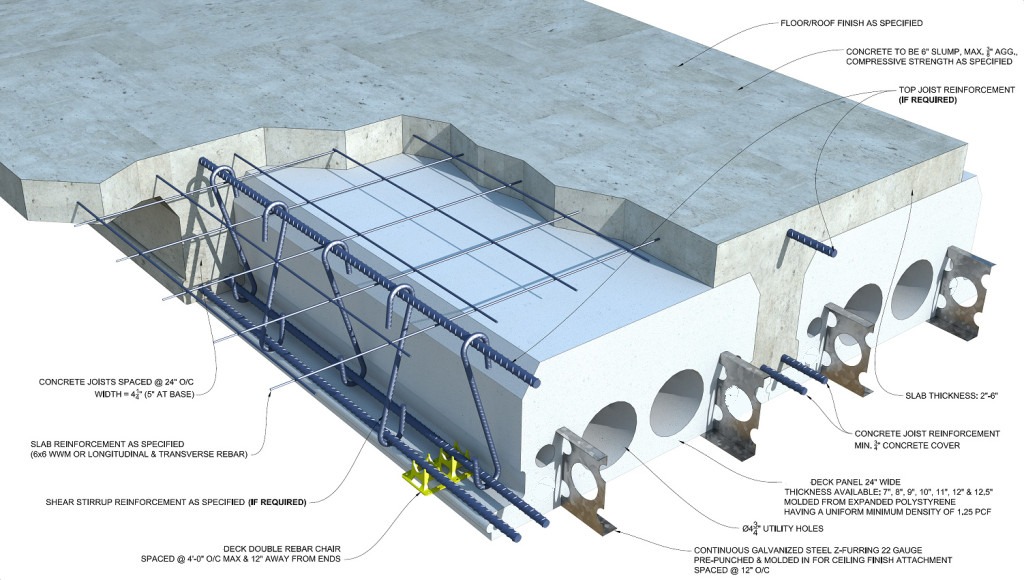

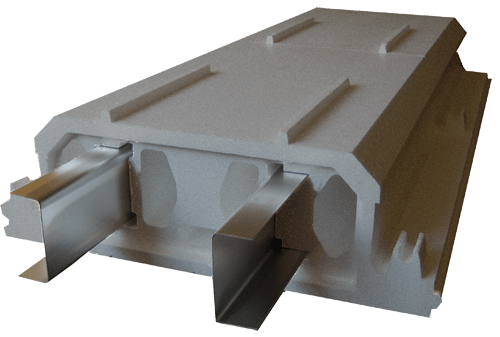

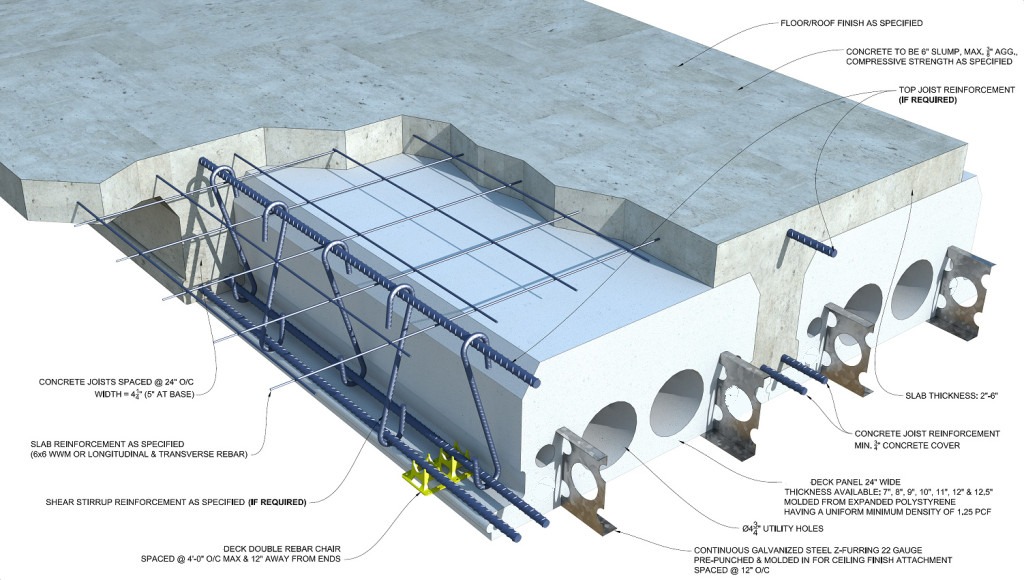

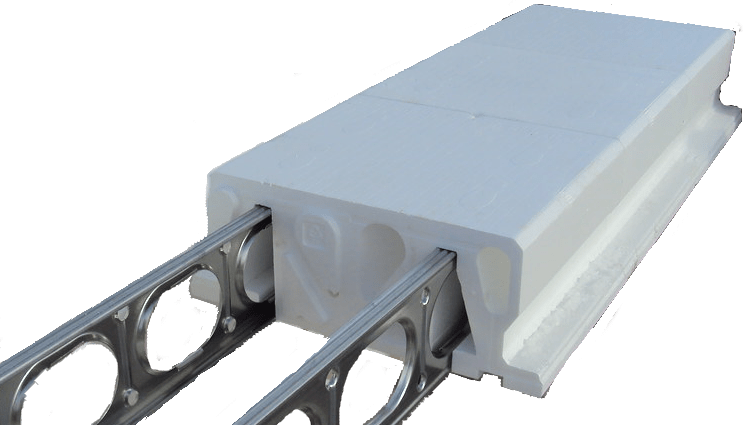

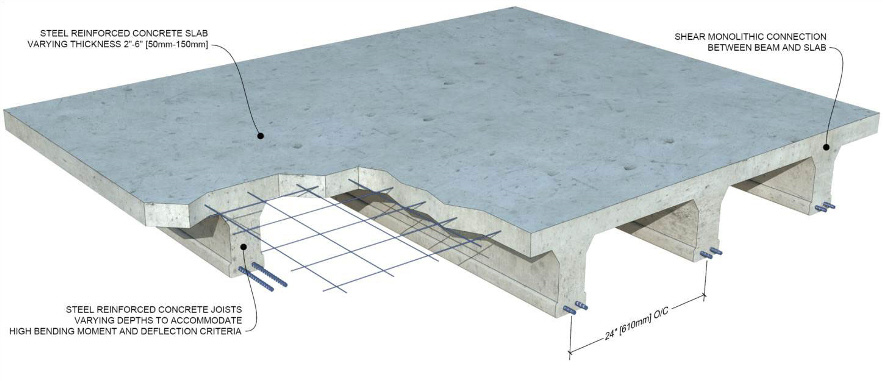

EPS-Deck is a very fast and versatile construction system for building Floors. The stay-in-place insulating concrete forms (ICF) are made of Expanded Polystyrene (EPS). EPS is a superior insulation material for many decades. To create formwork for support of concrete you need to insert steel beams into each EPS-Deck panel. After you place the reinforcement inside each beam hole. This way, you will have a slab formwork with minimal support for the construction load. The forms are lightweight so that two people can handle each panel with ease. EPS-Deck also reduces the floors’ weight, producing a T-beam shape. You will have a lightweight suspended slab instead of a conventional flat slab. When the slab will be ready you can attach ceiling finishes, such as drywall to the EPS-Deck forms.

Some producers use a continuous molding process. They can make concrete forms in different lengths. If you have ready concrete formworks in the exact size you can speed up on-site installation. Other producers make forms in 10 inches to 4-foot lengths. Short formworks easy to transport to the construction site. Then workers connect EPS-panels in the desired length. The concrete decking system is the result of years of research, design, and practical experience.

Concrete Deck Forming System

Why Homeowners Build with EPS-Deck

Quiet & Comfortable Interior

- Minimized air infiltration, no drafts or cold spots;

- High Sound Transmission Class ratings reduce the noise;

- Perfect for in-floor radiant heating.

Protection Against Disasters

- Built to withstand tornado-level winds & impact of flying debris;

- Fire-resistant Ratings of 1-4 hours;

- Elevated buildings cut or drop flood damage.

Lower Utility & Insurance Costs

- Reduced HVAC sizing requirements and energy bills;

- Lower insurance costs - significant savings in at-risk regions.

Durable & Low Maintenance

- Long-term durability and inherent safety of buildings constructed with reinforced concrete;

- It does not support the growth of mold or mildew;

- Reduced risk of water damage.

Why Construction Professionals Build with EPS-Deck

Fast & Easy Builds

- Lightweight panels, pre-cut to your specifications;

- Built-In Utility chases and steel furring strips;

- Self-reinforcing forms should only be temporarily supported every 6 feet.

The System is Very Flexible

- Available in thicknesses of 7" to 12½";

- Up to 33' clear spans are possible (with typical residential live-loads);

- Designed for easy integration with any ICF or block wall system.

Reduced Costs

- Saves on labor and adds less incremental mass to the structure;

- Uses up to 50% less concrete & 33% less steel compared to traditional concrete slabs.

Green Building

- Insulating, thermal mass, and low air-infiltration properties;

- Conforms to most of the requirements of the energy-saving program;

- Ideal for Green Roofs, Net Zero Energy Buildings (NZEB), LEED and Passive House designs.

Installation is quick and easy

Important advantages of EPS slabs are shorter construction and delivery times. They can be used with CMU, brick or ICF walls. This allows the builder to use one team to build the entire building, from the foundation to the roof. It is not necessary to rely on several separate subcontractors and suppliers. During operation, they also install insulation. Insulation can be partly removed after the concrete is cast. This drop individual furring and insulating crews for laying engineering networks. And there's no need for cranes and other heavy equipment besides a concrete pump for the pour.

The assembly is ready to accommodate the finishing materials. In the lower part, the crew can screw plaster or drywall to the integrated furring strips. And in the upper part - any kind of finishing required or desired.

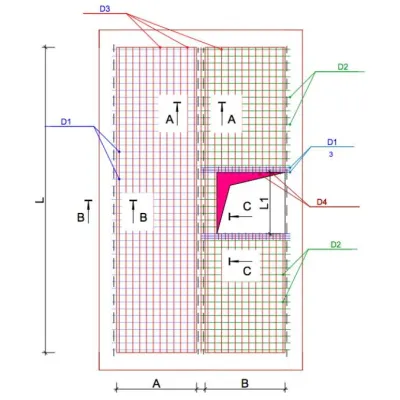

Wide range of spans and R-factors

EPS-Deck formwork is available in 7 different thicknesses (7''', 8''', 9''', 10''', 11''', 12''' and 12.5''), creating concrete beams from 5'' to 10.5'' deep. The R values range from R-16 to R-33. Some factories produce panels with the lengths required for your construction project. This eliminates labor and material costs. Some plants produce short panels that are assembled on site. This reduces the cost of delivery. In both cases, you can make spans of up to 33 feet using conventional construction methods and residential live-loads. For longer spans or higher loads use special techniques or auxiliary structural supports.

Reduced Shoring during Construction

EPS-Deck needs to be supported underneath with typical shoring, usually about 6 feet apart. The structural engineer or shoring engineer handles the correct layout and specifications. EPS-Deck acts as its own formwork so no plywood is required. The crew doesn't need to install and stripe plywood making work quicker.

Carry Loads and Maintain Structural Integrity

EPS-Deck forms one-way suspended concrete slabs. This eliminates up to half of the reinforcing steel because the load is transferred to two walls or beams, not four. It also eliminates up to 40 percent of the weight of the floor. This means that supporting elements can be smaller as well. You still get a structure with clear spans of over 30 feet supporting normal residential floor loads.

How to Increase Spans

To increase spans use intermediate supporting beams. Put this beam perpendicular to the T-Beams to carry loads across clear spanned areas. These beams can be separate from the slab structure. But usually, they are cast-in-place as part of the slab structure. To create longer spans use EPS Top Hat - an extra piece of EPS. Or use post-tensioning in the bottom of the T-Beams instead of conventional rebar. A licensed engineer will need to stamp the drawings before submission to the building department.