Increasingly, developers in the house are making a monolithic suspended slab. What do you need to know before you choose this option?

What does it take to make a monolithic slab?

We need a technical drawing. The engineer, having made the calculation, will define the optimum thickness of the slab and its reinforcement. This is the only way to make the slab in your home really economical.

You need to find a builder who will provide quality work, and will not strain you with the search for formwork, scaffolding and materials. Find out if his company has a license. But most importantly, it's a reputation confirmed by acquaintances. House you build for life, and children with grandchildren in it will have to live, so find the most responsible professionals.

What should a competent and experienced builder know?

Certainly, he must be able to read the drawings, otherwise the work ordered by you may be a waste of time and money. Now there are a lot of grief-builders who claim: why do I need a blueprints, I know how to do it better and cheaper. If you are caught with such "doityourself", refuse to work with them, and look for specialists. What else? A builder must know the technology to produce concrete work. There are many nuances to be provided during the construction. Concrete protective cover for the main reinforcement, jointing the reinforcement, placing it on the support, arrangement of the pouring joints, maintenance of the concrete curing after the pouring and compaction of the concrete mixture with vibrators ... All these, and much more, is a prerequisite for the quality of work.

What kind of concrete is needed for a monolithic slab?

The strength class of concrete depends on the results of the slab calculation. Generally, concrete classes M15, M20 and M25 are accepted - the more spans and loads, the higher the concrete class. Concrete have frost resistance and watertightness requirements in addition to their strength class. The following grades are sufficient for the slabs of heated buildings: frost resistance F50, water resistance - not regulated. If there are balconies in the slab, the required frost resistance and watertightness grade depends on the climatic region.

What kind of reinforcement is used to reinforce a monolithic slab?

Main reinforcement is used in class 500N (grade 60), hot-rolled deformed steel rebar. Diameters of main rebar vary from 8 to 16 mm. The main reinforcement is the bottom, due to the fact that the floor works in a bend, and the most stretched is the bottom zone of the slab (and therefore the most reinforced). The upper reinforcement is often accepted structurally and its diameter can be smaller than that of the lower one. The only exceptions are the slab areas at the resting points, where reinforcement is often calculated in the upper area of the slab. And in the case of large spans, as well as when resting on columns, there is a need to install cross reinforcement in the form of U-rebar or brackets. Cross reinforcement class 250N (grade 40).

What is the optimal thickness of the slab?

Everything depends on the span, i.e. the distance between walls or columns. Thickness of the slab is decided based on span to depth ratio specified in IS456-2000. For a residential building, the thickness of the slab can vary between 150 ... 200 mm. Moreover, the thickness of the slab over 180 mm should be justified by the calculation, because increasing the thickness of the slab significantly increases the load on it, and in certain cases, worsens the work.

How to Reinforce the Suspended Slab of a Residential Building?

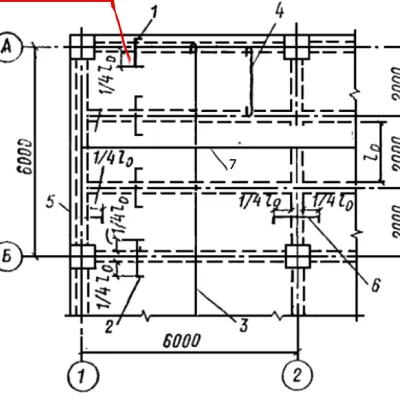

The most common scheme for a two-storey house is a One Way Slab (loadbearing walls along the perimeter of the house plus one wall in the middle). The differences are mainly in the size of the house in the plan and location of the stairway opening.

This article will offer options for reinforcing such a slab for different sizes of the house.

The structural scheme is as follows: the slab rests on only three longitudinal loadbearing walls (One Way Slab). Transverse (external) walls, as well as the walls of the staircase (if any) are self-supporting. Thus, we kill two hares at once: 1) save on the size of foundations for self-supporting walls, and the wall itself can be made lighter and thinner (justifying the savings by the calculation, of course, - on the load-bearing capacity and thermal engineering); 2) now the reinforcement of our floor will not depend on the length of the house L and width of the stairwell L1, and only the width of the spans of A and B.

Minimum reinforcement is 0.12% for HYSD bars and 0.15% for mild steel bars. The diameter of bar generally used in slabs are: 6 mm, 8 mm, 10 mm, 12mm and 16mm.

The maximum diameter of bar used in slab should not exceed 1/8 of the total thickness of slab. Maximum spacing of main bar is restricted to 3 times effective depth or 300 mm whichever is less. For distribution bars the maximum spacing is specified as 5 times the effective depth or 450 mm whichever is less.

Attention, if you want to support the slab on all four exterior walls (Two Way Slab), the reinforcement must be completely different! This scheme is not designed for this.

The materials for our slab will be as follows:

- heavy concrete class M25;

- main reinforcement of Thermo Mechanically Treated Deformed Steel Ba, rebar class 500N (grade 60) is Deformed Steel Bar with crescent ribs;

- distribution steel and dowels made of mild steel bars of class 250N (grade 40).

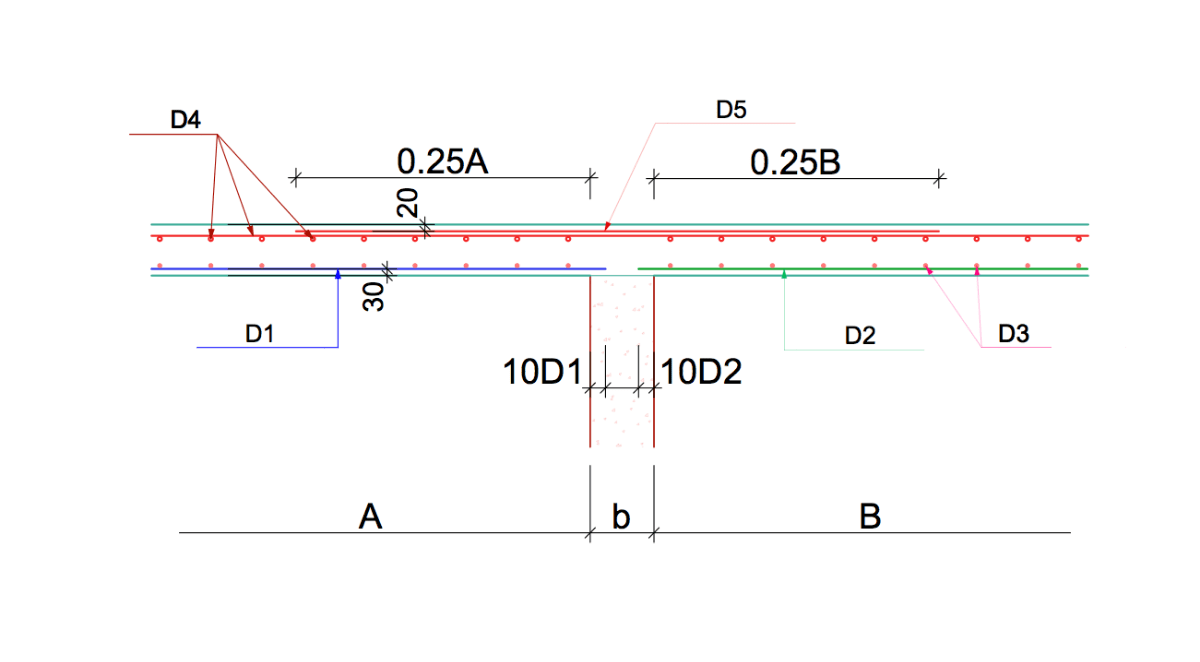

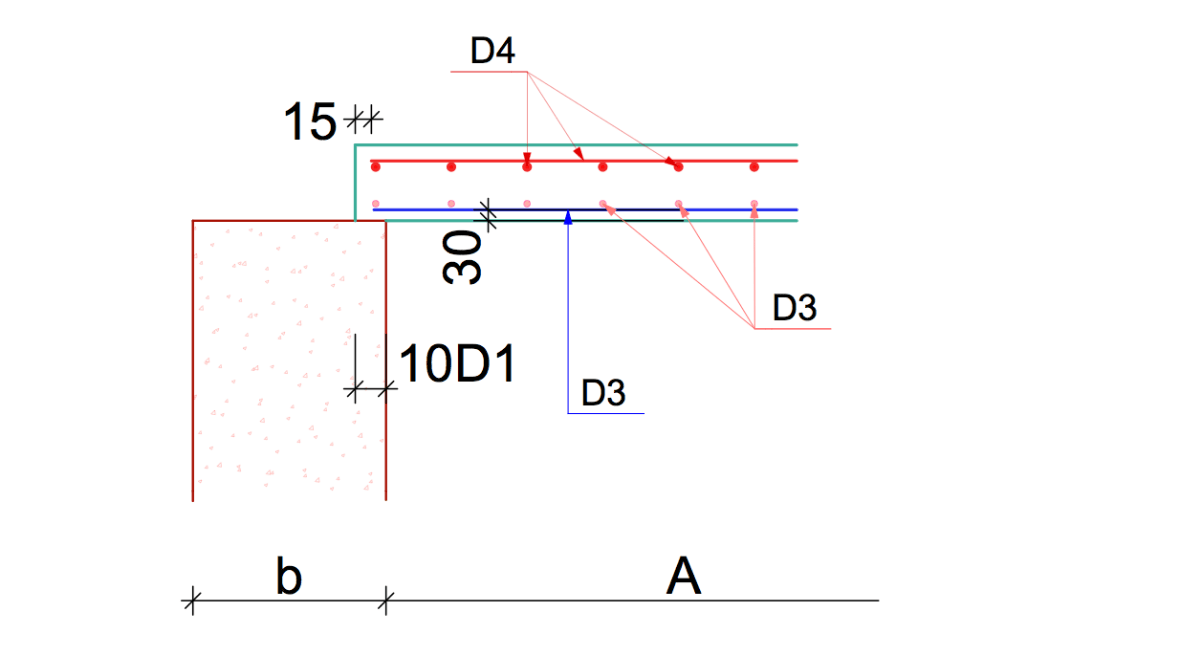

The protective concrete cover for the main bottom reinforcement is 30 mm, for the upper reinforcement - 20 mm.

We accept the following loads on the slab (normative loads are given):

- from floor construction 150 kg/m2 (30.7 psf);

- from the weight of the partitions 50 kg/m2 (10.2 psf);

- live load (from people, furniture, etc.) 150 kg/m2 (30.7 psf).

The floor covering is not designed to support any props (roof supports, for example). Supporting the platform of the stairs as well as the stringers leading from the ground floor is allowed.

Construction area - no seismic.

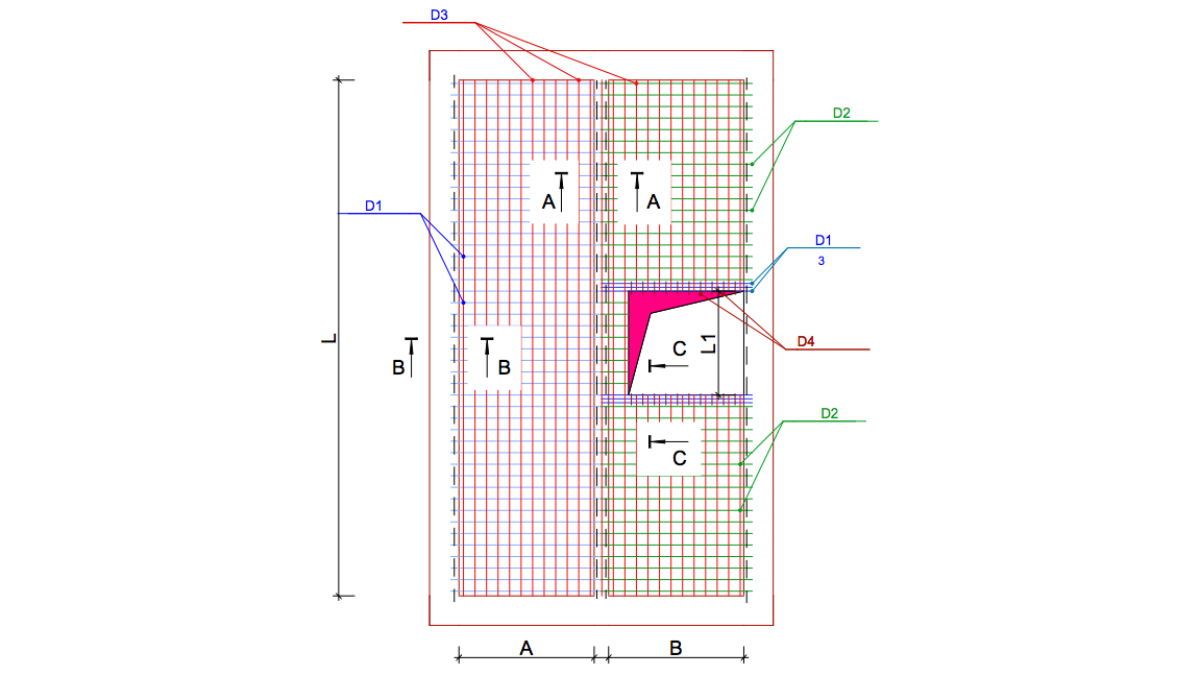

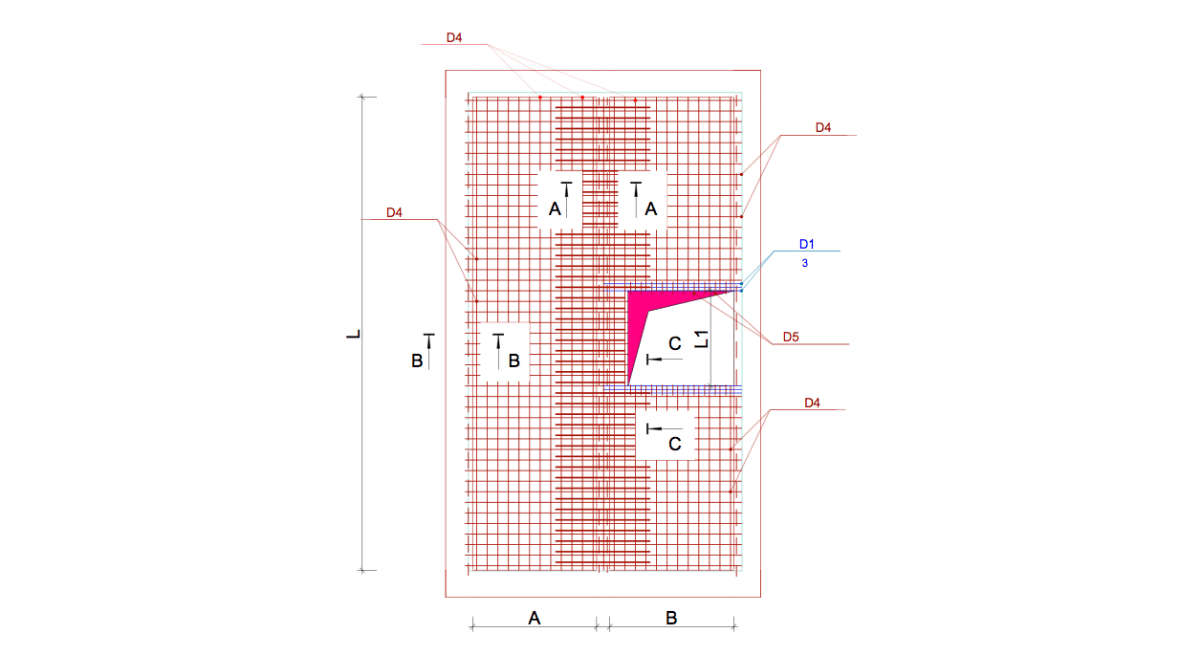

Lower and upper reinforcement of the slab is shown in the picture.

Lower slab reinforcement

Top slab reinforcement

Section A-A shows the reinforcement of the slab above the middle wall.

Section B-B shows the reinforcement of the slab above the outer walls.

Section C-C shows the reinforcement of hidden beams framing the stairway.

D5 is ringbeam spaced on 200 mm (8") o.c made of mild steel d6 (#2).

The reinforcement of the slab is summarized in the table.

| D1, mm | D2, mm | D3, mm | D4, mm | D5, mm |

| А = 3 m, В = 3 m, slab thickness 150 mm | ||||

| 8 500N (grade 60) s.200 o.c. | 8 500N (grade 60) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 8 500N (grade 60) s.200 o.c. |

| А = 3,5 m, В = 3,5 m, slab thickness 150 mm | ||||

| 8 500N (grade 60) s.200 o.c. | 8 500N (grade 60) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 8 500N (grade 60) s.200 o.c. |

| А = 4 m, В = 4 m, slab thickness 150 mm | ||||

| 10 500N (grade 60) s.200 o.c. | 10 500N (grade 60) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 10 500N (grade 60) s.200 o.c. |

| А = 4,5 m, В = 4,5 m, slab thickness 160 mm | ||||

| 10 500N (grade 60) s.200 o.c. | 10 500N (grade 60) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 10 500N (grade 60) w. 150 or 12 500N (grade 60) s.200 o.c. |

| А = 5 m, В = 5 m, slab thickness 180 mm | ||||

| 12 500N (grade 60) s.200 o.c. | 12 500N (grade 60) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 12 500N (grade 60) s.200 o.c. |

| А = 5,5 m, В = 5,5 m, slab thickness 180 mm | ||||

| 12 500N (grade 60) s.200 o.c. | 12 500N (grade 60) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 12 500N (grade 60) w. 150 or 14 500N (grade 60) s.200 o.c. |

| А = 6 m, В = 6 m, slab thickness 180 mm | ||||

| 14 500N (grade 60) s.200 o.c. | 14 500N (grade 60) s.200 o.c. | 8 250N (grade 40) s.200 o.c. | 8 250N (grade 40) s.200 o.c. | 14 500N (grade 60) s.200 o.c. |

| А = 6 m, В = 5,5 m, slab thickness 180 mm | ||||

| 14 500N (grade 60) s.200 o.c. or 12 500N (grade 60) w. 150 | 12 500N (grade 60) s.200 o.c. | 8 250N (grade 40) s.200 o.c. | 8 250N (grade 40) s.200 o.c. | 14 500N (grade 60) s.200 o.c. |

| А = 6 m, В = 5 m, slab thickness 180 mm | ||||

| 14 500N (grade 60) s.200 o.c. | 10 500N (grade 60) s.200 o.c. | 8 250N (grade 40) s.200 o.c. | 8 250N (grade 40) s.200 o.c. | 14 500N (grade 60) s.200 o.c. |

| А = 6 m, В = 4,5 m, slab thickness 180 mm | ||||

| 14 500N (grade 60) s.200 o.c. | 8 500N (grade 60) s.200 o.c. | 8 250N (grade 40) s.200 o.c. | 8 250N (grade 40) s.200 o.c. | 14 500N (grade 60) s.200 o.c. |

| А = 6 m, В = 4 m, slab thickness 180 mm | ||||

| 14 500N (grade 60) s.200 o.c. | 8 500N (grade 60) s.200 o.c. | 8 250N (grade 40) s.200 o.c. | 8 250N (grade 40) s.200 o.c. | 14 500N (grade 60) s.200 o.c. |

| А = 5 m, В = 4,5 m, slab thickness 180 mm | ||||

| 12 500N (grade 60) s.200 o.c. | 8 500N (grade 60) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 6 250N (grade 40) s.200 o.c. | 12 500N (grade 60) s.200 o.c. |

The decoding of the values in the table is as follows:

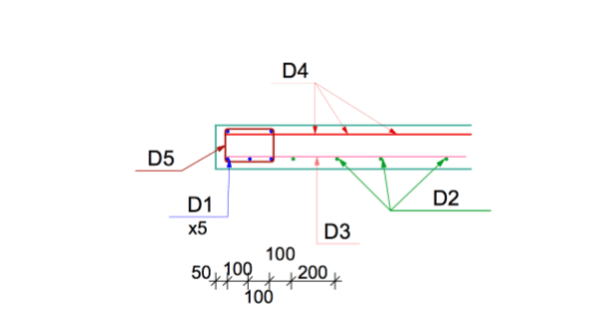

D1...D5 - slab main reinforcement shown in the figures above;

8 A500N s. 200 o.c. - reinforcement with diameter of 8 mm of deformed steel bar of 500N class, spaced 200 mm o.c.;

A = 3 m - the width of the first span in light between the walls is equal to 3 m;

B = 4 m - the width of the second span in the light between the walls is equal to 4 m.

What features should be considered when reinforcing the slab?

Lower rebar, first layer. The main reinforcement D1 and D2 is placed from the wall to the wall with extention of 10 diameters (if the diameter of the reinforcement is 12mm, it should be placed on the wall by 10*12 = 120mm), the end of the reinforcement should not be brought to the edge of the slab by 15 mm, i.e. the slab should rest on the wall by 10d+15 (for the reinforcement with 12mm diameter it is 10*12+15 = 135mm) - this is the minimum size, the support can be larger, but not smaller. The main reinforcement D1 and D2 is the first layer of lower rebar, the concrete cover up to the edge of this rebar is accepted 30 mm. These rebars must not be lapped together!

Hidden beams at the stairway opening. After the first layer of reinforcement has been laid, the reinforcement must be tied together with hidden beams, which will frame the stairway opening. To do this, you need to lay three D1 rods spaced 100 mm o.c below and two D1 rods spaced 200 mm o.c. above, and tie this bar with ring beam of 6 250N spaced 100 mm o.c.

Lower rebar, second layer. D1 and D2 rebars are placed perpendicular to D3 distribution rebar, it is a mild rebar of 250N class, it must be placed on the wall as well as the first layer. All mild reinforcement at the ends should end with bends, "legs" that look like hooks, the length of these bends is equal to 6d (for reinforcement with diameter of 8 mm the part to be bent is equal to 6*8 = 48 mm). This reinforcement can be joined by a lapsplicing, the lapping size is 250 mm. The D3 rebars must be connected to D1 and D2 by a staggered binding wire (so that 50% of the crossovers are connected). Supporting elements made of 250N8 reinforcement should be mounted on the bottom mesh in 600x600 mm staggered order. How to perform these elements can be found in "Guidelines for the construction of concrete and reinforced concrete structures made of heavy concrete". The upper mesh of the reinforcement will be laid on these elements.

Upper reinforcement, first layer. The first layer of D4 upper reinforcement is laid parallel to the middle wall spaced 200 mm o.c. This is a mild reinforcement, so it must be treated in the same way as the lower reinforcement of the second layer.

Upper rebar, second layer. The second layer of reinforcement D4 is laid perpendicular to the first layer, tie it with wire twists in a staggered order. Then we need to lay the main reinforcement D5 above the middle wall. This deformed steel rebar 500N, it is stacked perpendicular to the middle wall. The length of rebars is determined on the basis of the fact that in the direction of each span rebar should enter the ? distance between the walls. That is, if we have two spans of A and B, and there is a wall of b thickness, the length of the rebar D5 will be equal: 0.25A + 0.25B + b. If one span is larger than the other, then D5 rods enter each span for its own length, equal to ? span. When placing the upper reinforcement of the first and second layer, it should be taken into account that D5 is the rebar of the largest diameter, and it is for this rebar that a concrete cover of 20 mm should be maintained - all this should be calculated before the beginning of the manufacture of supporting elements, so that their height kept the upper mesh at the right distance from the bottom.

Well, in conclusion: the concrete has to be vibrated. The formwork can be removed after 28 days.