Fiber-cement siding has been around for a long time. The name - fiber-cement siding - the panel received due to its composition based on artificial or natural fiber (cellulose fibers) and cement. They are added silica sand, water, and mineral additives.

The technology of manufacturing the panels is quite complicated, but it can be described as follows in a nutshell. The solution of the ingredients listed above is mixed, pressed, and dried. The finished material is used to make panels with a width of 4 to 12 inches. As a result, they have high strength, fire safety, and environmental friendliness.

History and Geography

Fiber cement siding was first produced in Japan in the middle of the last century. To this day, the Japanese product is considered the benchmark. According to experts, the European fiber-cement siding is silver, and the Japanese are gold. And among the European materials is highly prized Belgian siding. You can also buy and domestic fiber-cement finishing material. It is somewhat cheaper than its imported counterparts but quite competitive.

Advantages of fiber cement siding

Innovative production technology and carefully selected composition make it possible to achieve a really high quality of the final product. In terms of its strength, such finishing is not inferior to stone, so it could be called stone siding.

The advantages of fiber cement finishes are quite a lot:

- First, the combination of cement and cellulose fibers gives the material high strength, rigidity, and plasticity at the same time.

- Due to the relatively large thickness and the inner panels are not hollow - they do not "walk" and are not bent. If they lean or lean against a wall, something heavy.

- Fiber-cement siding is waterproof. Also, it is resistant to corrosive environments so that it can be installed in homes near the sea, in regions with high humidity and precipitation levels.

- Fiber cement is not susceptible to infection by fungi and other microorganisms.

- Panels can operate at temperatures of -40 ... +140 ° F. And if they have a glass-ceramic coating, this range increases to -58 ... +176 ° F. Besides, siding is resistant to rapid fluctuations in temperature.

- Frost resistance panels, on average, 200 cycles.

- Fiber cement siding is resistant to UV radiation, does not fade in the sun, and retains color strength for 10-15 years.

- Panels can be cut and repainted. To do this, use special paint based on acrylates.

- Fiber cement siding has reasonably high sound insulation.

- Panels do not support combustion.

- Siding is environmentally friendly.

- Such finishing looks attractive. The broad range of colors and textures allows you to choose the appearance of the house's facade.

- The installation process of siding - dry, without the use of adhesives and compounds. Therefore, you can finish the house at any time of year.

- Fiber cement panels do not require special care. They are resistant to active substances. They can be cleaned with non-abrasive detergents or simply with water from a hose.

Once you learn a few elementary techniques, such as cutting and nailing, fiber-cement siding is simple to install and goes on one plank at a time. You can sometimes fix the siding directly to studs that have been covered with house wrap. However, in high wind and earthquake areas, siding often has to be nailed on walls that have been sheathed with plywood or OSB panels. These panels add lateral and structural strength to a building.

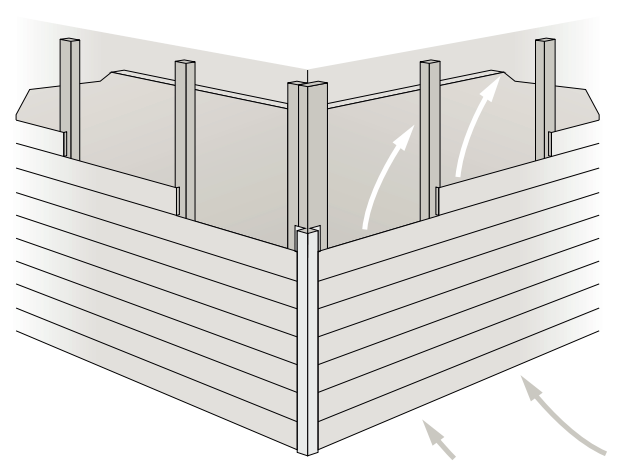

And even though еhe fiber cement boards themselves do not need to be ventilated, it is recommended to leave an air gap of at least 1" behind the siding boards. It is necessary to ventilate the wall to prevent condensation that appears for one reason or another on the building's wall. The gap at the bottom is subsequently closed with a perforated profile to shield against insects and rodents.

Fiber-cement clapboard siding comes in various sizes that are usually 12 ft. long and 5⁄16 in. thick. You can find smooth or wood-grain textures as you wish. In addition, you can purchase ready-to-install fiber cement boards in a wide range of beautiful colors and stains. Or you can prime and paint them on site. Whichever method you use, you will need to coat with latex paint all cut ends before installing the siding. Typically, this is done at the saw by the person cutting the siding. Then, you can immediately install it.

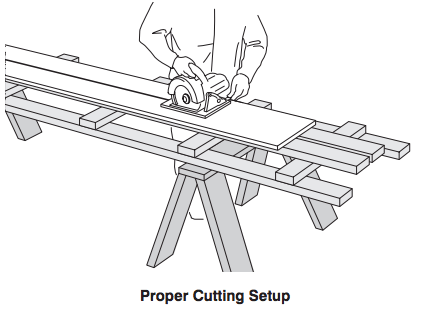

Cutting tips

You can cut fiber-cement siding with a regular circular saw and a conventional carbide blade, but a diamond-tipped masonry blade with four to six teeth works much better and is probably cheaper in the long run. When fiber cement is cut or drilled, it will create dust. This dust may contain crystalline silica, which can pose a health risk. It is preferable to use a set of electric shears to produce less dust than high-speed tools. They cut with relatively little effort, less noise, and virtually no dust. For small holes, such as those for exterior electrical outlets, use a jigsaw with a carbide-tipped blade. Cut round holes for pipes with a carbide-tipped hole saw mounted in a heavy-duty, two-handled drill.

- Cut fiber cement board face down when using a circular saw or mechanical shears. Cover the saw table with a piece of carpet or softcover to avoid scratching the face of the siding.

- Cut fiber cement board face up when using a chop/ miter saw.

- When cutting fiber cement, support the board along its length and near the cut.

- To avoid breakage, use extra care when you cut near the edge.

- Handle narrow and notched pieces carefully to avoid breakage.

- When cutting the beaded siding profile, start the cut against the bead.

- When cutting Fiber Cement Cedar Lap Siding with CertainTeed ColorMax® finish, leave the protective film in place until the siding is nailed to the substrate; then remove it before applying for the next course.

Corrosion-resistant fasteners

Most companies guarantee their fiber-cement siding for 50 years. Therefore, it will last a long time—provided it's adequately attached with high-quality, corrosion-resistant, double hot-dipped galvanized or stainless steel. Do not use electro-galvanized nails because they corrode faster, especially in coastal areas. Nails should penetrate through the sheathing and at least 1” into studs.

A pneumatic nail gun designed for siding applications is faster than hand nailing. When using a pneumatic nailer for installing fiber cement siding to wood, adjust the air pressure to meet job site conditions, typically 80–85 psi. You also can nail fiber-cement siding by hand. However, fiber cement is harder than wood, so be sure the nails are well set before driving them. It may be necessary to predrill the holes at the corners to prevent the edges from breaking. It's a good idea to have a pocket full of felt strips (3 in. by 8 in.). Each time you have two pieces of siding meet at a butt joint, slip a piece of felt behind the joint and let it lap down on the lower course about an inch. This will help prevent water from entering the joint.

Trim details

You can butt the siding against the corner boards or cover it with aluminum corner pieces (called siding corners). These pieces have been used for many years as trim for wood siding. They can work just as well with fiber-cement siding. You should install the siding first and stop precisely at the corner. After all the siding is in place, you slip the siding corners under each course. A flange at the bottom of the corner hooks a row of siding, and then you drive a 6d or 8d galvanized nail through a hole in the top to hold it in place.

Installing siding panels

The installation details for fiber-cement siding are similar to those for wood clapboards. You will begin with a starter strip with weep holes that will allow moisture to escape readily. Next, you will need a clearance from the grade that either follows installation instructions or local building codes (whichever is greater). Then you would install your fiber cement corner and window trim.

Position your first course of siding ¼-inch below the starter strip and nail the siding into the studs 1-inch down from the top of the siding. Use galvanized siding nails and make sure that the nails penetrate a minimum of 1-1/4-inches into the framing. Do not overdrive the nails. Keep the nails flush to the siding. And it is recommended to put a flashing strip behind each butt joint to allow for water runoff.

Continue installing each course, making sure to leave a gap that the manufacturer requires at all trim locations, such as around windows and doors and at the edges of the installation to receive caulk. Except for larger widths, fiber cement siding is blind nailed. The one nail that holds the siding is hidden behind the next row of lap siding. After you know, the amount of revealing the siding will have, you can establish the height of each course. For example, a typical lap on 81⁄4-in.-wide siding is 11⁄4 in., which leaves a 7-in. reveal. You can mark this reveal on each piece of corner trim and every door and window all around the house by using a story pole. Then adjust a reveal up or down slightly (up to 1⁄2 in.) to fit siding pieces around door and window openings and maintain a uniform distance between the top of the wall and the uppermost siding course. To make sure the last course of siding will be uniform in width, measure down from the top of the wall frequently (every other course or so) and fine-tune the reveal, if necessary.

Fiber cement siding is 12 feet long, which means that siding on your longer walls will need to join together. Joining boards together is actually very easy - you should join boards in “moderate contact.” This means that the boards should be touching each other when they are installed. Therefore, there is no need to leave a gap for expansion.

You can mix and match siding to add a bit of style to a building. Gable ends can be sheathed with a different type of siding than the walls. T1-11 in the gable end, for example, will contrast with lap siding on the walls. Contrasts can be made even more remarkable by painting the walls a different color than the gable end.