Why you should insulate your home with sprayed cellulose

Does cellulose insulation react to moisture?

Let's look at a typical wooden frame house built of 5x15 or 5x10 boards with a vapor barrier film inside. This system works well from the inside because the vapor barrier film restricts moisture from entering the walls, and seeping inside, stays frozen for most of the winter. In the spring, the walls thaw out, and the water evaporates to the outside.

Ecowool insulation

But when you add an exterior layer of foam, a common practice for energy conservation, the walls won't dry out from the outside. Is this good or bad for the walls? It all depends on how thick the sheet you added outside (e.g., 15 cm of EPS foam for a 5x10 board wall)-the cladding and framing will stay pretty warm to prevent condensation, improving overall moisture levels. If you haven't added enough insulation, you've pushed the wall sheathing into a dangerous zone of freezing and high moisture.

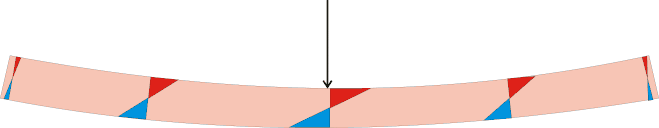

We learned from earlier research how to use mineral wool and EPS and XPS foams in various wall systems to improve energy efficiency while avoiding moisture problems. This latest study will show how cellulose behaves in different wall structures over 18 months. These will not be standard walls - no vapor barrier film is precisely planned for them, as we wanted to force moisture inside the walls.

Cellulose insulation

Cellulose insulation is most commonly made from recycled paper. As a local and relatively inexpensive product, it has recently become more prevalent in buildings built in Alaska. "Compacted" cellulose is blown inside the wall until it reaches a density of 60 pounds per cubic meter; this calculated density protects the insulation from crumpling over time. Compacted cellulose has a thermal conductivity coefficient of 0.036W/s-m, slightly lower than mineral wool and somewhat higher than EPS foams.

Our study showed that cellulose resists moisture better than either mineral wool or EPS insulation when used correctly. The test wall insulated with cellulose inside and outside showed lower moisture levels (and caused less condensation and mold growth) than the test wall insulated with mineral wool inside and foam outside.

This may be due in part to the properties of cellulose (eco wool). Compacted eco wool is less air permeable than mineral wool boards. Thus, when used as interior insulation, it reduces the amount of moisture passing through the wall cavities between the studs.

Cellulose absorbs and releases water vapor, allowing the moisture level in the wall cavity to be normalized and preventing a significant increase in moisture, the cause of rot and mold.

Ecowool is also more resistant to water vapor than EPS or XPS boards. The wall tested, insulated with cellulose on the outside, showed lower moisture levels than the wall insulated with Styrofoam because the wall dries out faster on the outside.

This study shows that compacted eco wool can provide better thermal protection as exterior insulation than polystyrene foam sheets. In future research, we will find the minimum thickness of insulation needed to keep the exterior cladding warm and dry.